Difference between revisions of "Tajima TMEF"

| (15 intermediate revisions by 2 users not shown) | |||

| Line 10: | Line 10: | ||

}} | }} | ||

[[File:Tajima TMEF-H620.jpg|right|thumb|alt=Tajima TMEF-H620 6 head flat machine|Tajima TMEF-H620 6 head flat machine]] | |||

The [[Tajima TMEF]] were flat machines besides a few exception models. | |||

TMEF came in several different models such as the TMEF-HCG, TMEF-S, etc. | |||

TMEF machines are [[Embroidery_Machine_Legend#Bridge_Type|bridge type]] embroidery machines. | |||

==TMEF Series & TMEF H== | ==TMEF Series & TMEF H== | ||

| Line 16: | Line 21: | ||

TAJIMA is the technological leader in the embroidery industry. | TAJIMA is the technological leader in the embroidery industry. | ||

<center> | |||

{| class="wikitable sortable" | |||

|- | |||

! Model !! Heads !! Needles !! EMB Space / Head !! Max SPM !! Pwr Cons. !! Years !! Color | |||

|- | |||

| TMEF-HC606 (G1) || 6 || 6 || emb Space || SPM || POWEW || 1990-1992 || Green | |||

|- | |||

| TMEF-HC612 (G1) || 12 || 6 || emb Space || SPM || POWEW || 1990-1992 || Green | |||

|- | |||

| TMEF-HC904 (G1) || 4 || 9 || emb Space || SPM || POWEW || 1990-1992 || Green | |||

|- | |||

| TMEF-HC906 (G1) || 6 || 9 || emb Space || SPM || POWEW || 1990-1992 || Green | |||

|- | |||

| TMEF-HC912 (G1) || 12 || 9 || emb Space || SPM || POWEW || 1990-1992 || Green | |||

|- | |||

| TMEF-HC906 (G2) || 6 || 9 || emb Space || SPM || POWEW || 1993-1994 || Green | |||

|- | |||

| TMEF-HC912 (G2) || 12 || 9 || emb Space || SPM || POWEW || 1993-1994 || Green | |||

|- | |||

|} | |||

</center> | |||

'''FEACTURES & FUNCTIONS''' | |||

[[File: Reader.jpg|thumb|right| Reader/Handler (option)]] | |||

[[File: Jacquar.jpg|thumb|right| JACQUARD Reader (option)]] | |||

*'''ACCURATE FRAME DRIVE & POWERFUL MAIN-SHAFT DRIVE MOTOR.''' | |||

A special stepping motor featuring almost permanent life and extremely high accuracy is used for assuring stable frame driving. | |||

*'''SPEED CHANGE''' | |||

Simple knoh control or (push a numeral key) of infinitely variable speed (within range), and two speeds controlled by tape data (computer) to reduce thread breakage. | |||

*'''FRAME BACK''' | |||

If embroidery is damaged because of a thread break or bobbin runout, the frame can be moved backward to the starting point (500 stitches) if operating from tape. Once restarted the machine sews independently on heads where damage occurred before automatically restarting all heads. | |||

* '''FRAME FORWARD''' | |||

Frame can be manually stepped forward without stitching | |||

*'''LON G LASTING STORAGE OF TAPE DATA''' | |||

If the machine is stopped in the middle of a design and left idle for a long time, the tape data remains stored in memory or (buffer). When restarted the machine will begin to sew at the exact spot where it was stopped | |||

*'''DESIGN COODINATE CHANGE SYSTEM''' | |||

16 [8] symmetrical desing positions are possible in 45 degree [90 degree] increments at the push of a button. | |||

*'''PATENTED AUTOMATIC NEEDLE BAR SELECTOR (FOR EASY NEEDLE/ COLOR SEQUENCING)''' | |||

Needle bars can be selected for any color change sequence. Color change is possible up ti 99 times. | |||

*'''JUMP STITCH DEVICE''' | |||

*'''AUTOMATIC REPEAT''' | |||

Embroidery of a design having the same color pattern can be automatically repeated up to 81 [9] times when operating from memory. [ 9 times when operating from tape] | |||

==TMEF== | ==TMEF== | ||

[[File:MACHINE2.gif|200px|thumb| | [[File:MACHINE2.gif|200px|thumb|left|TAJIMA TMEF 900 series,]] | ||

With the addition of the TMEF-S series (streamlined with useful functions for easier operation) the TMEF series is now complete. It is the top model series in the embroidery industry today. | With the addition of the TMEF-S series (streamlined with useful functions for easier operation) the TMEF series is now complete. It is the top model series in the embroidery industry today. | ||

| Line 26: | Line 87: | ||

The 300 series (3-needle), 400 series (4-needle), and the 600 series (6-needle) are available in many configurations with 6 to 24 heads and from standard to large embroidery design fields. | The 300 series (3-needle), 400 series (4-needle), and the 600 series (6-needle) are available in many configurations with 6 to 24 heads and from standard to large embroidery design fields. | ||

===Brochure=== | |||

The following information has been taken from a Tajima TMEF Brochure: | |||

''THE TMEF SERIES IS THE INDUSTR’S ANSWER TO THE EVER-CHANGING REQUIEREMENTS IN THE WORLD OF FASHION.'' | |||

====SETTING CAPACITY==== | |||

[[File:Capacity.jpg|thumb|right|SETTING CAPACITY.]] | |||

#Sealing (up/down)1%-100%(original size)-100% | |||

#Stitch density of the satin and/or the fill stitch (increase/decrease)-90% - 0%(original size)-100% | |||

#Stitch length of the fill and/or the running stitch (increase/decrease)-90% - 0% (original size) -100% | |||

#Enlarge or reduce your design and let TSP change the stitch density automatically. | |||

#Rotate your design to any angle. | |||

#A design can be mirrored by centering on Y axis. | |||

*TSP TAJIMA STITCH PROCESSOR (Option) | |||

*TRUE SCALING (UP AND DOWN) OF DESIGN TAPES WITH TAJIMA’S REVOLUTIONARY TSP WITH AUTOMATIC STITCH DENSITY COMPENSATION…AND MORE!! | |||

==TMEF-H== | |||

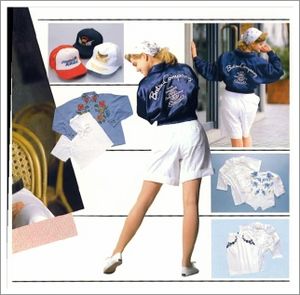

[[File: GIRLS.jpg|thumb|right|TAJIMA, DESIGN]] | |||

===Brochure=== | |||

The following information has been taken from a Tajima TMEF Brochure: | |||

====The Creative approach to faschion==== | |||

With a small twist, an interesting desing or a delicious fragrance, an ordinary, everyday scene stars to look different. It´s the same way with the art of looking good. Toss out conventional ideas and jump into somethimg new. We at tajima want to help strengthen the bonds between the clothes and the wearer and help you create more exciting fashions. | |||

====That special touch of beauty:==== | |||

The pursuit of beauty is eternal Everyone Has some special quality, and some take the adventurous path in highlighting it. Today, attention is focusing on embroidery, which adds beauty and imagination to clothing and accessories. We at Tajima want to help you achieve those moments of creativity and realize them senstively, vividly, and any way you desire. | |||

'''''The Tajima TMEF-H machine dimension information'''''<br /> | |||

[[File: Cats1.jpg|200px|thumb|right|Tajima TMEF-H]] | |||

{| class="wikitable" | |||

|- | |||

! Models !! Heads !! Head Interval !! Emb. Space (D x W mm)!! All-head Border/Continuous Design (D x W mm) !! Table size (L x W mm) | |||

|- | |||

| TMEF-H608-908 || 8 || 400 || 450 x 400 || 450 x 3,200 || 1,340 x 4,220 | |||

|- | |||

| TMEF-H610-910 || 10|| 325 || 450 x 325 || 450 x3,250 || 1,340 x 4,195 | |||

|- | |||

| THEF-H610-910 || 10 || 400 ||450 x 400 || 450 x 4,000 || 1,340 x 5,020 | |||

|- | |||

| THEF-H612-912 || 12 || 275 || 450 x 275(550) || 450 x 3,300 || 1,340 x 4,470 | |||

|- | |||

| THEF-H612-912 || 12 || 345 || 450 x 345 || 450 x 4,140 || 1,340 x 5,110 | |||

|- | |||

| THEF-H615-915 || 15 || 275|| 450 x 275 || 450 x 4,125 || 1,340 x 5,020 | |||

|- | |||

| TMEF-H616 || 16 || 240 || 450 x 240 (480) || 450 x 3,840 || 1,340 x 4,960 | |||

|- | |||

| TMEF-H618 || 18 || 230 || 450 x 230 || 450 x 4,140 || 1,340 x 5,010 | |||

|- | |||

| TMEF-H620|| 20 || 200 || 450 x 200(400) || 450 x 4,000 || 1,340 x 5,020 | |||

|} | |||

''' TMEF H Table specifications''' | |||

{| class="wikitable" | |||

|- | |||

! '''Standard equipment'''|| 8-channel tape reader | |||

|- | |||

| '''Options''' || Additional IC multiplex Memory (256,000 stitches max)Under threas control, Boring device, Reader/Handler, Stitch processor, Floppy disck drive , Power condenser etc | |||

|- | |||

| '''Stitch length''' || Ternary scale :0,1 --12,1mm, Binary scale : 0,1 --12,7mm | |||

|- | |||

| '''Speed''' || Speed | |||

|- | |||

| '''Motor'''|| Speed variable motor x 1. Stepping motor x 2 | |||

|- | |||

| '''Electricity''' || 3-phase 220V/380V. 50Hz/60Hz Single-phase 200V,220V,230V,240V. 50Hz/60Hz | |||

|- | |||

| '''Electric consumption'''|| 1,0Kw ( 3 phase 200V) | |||

|} | |||

==Main Feactures and Functions for the H-series== | |||

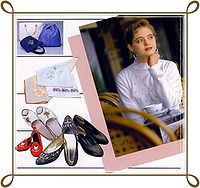

[[File: Cats2.jpg|200px|thumb|right|product sample]] | |||

*'''Accurate Frame Drive''' | |||

For stable frame driving,special stepping (pulse) motors are used. These motors feature an almost permanent life and pin-point accuracy. | |||

''' | *'''Automatic Needle Bar Selector (Pantented)''' | ||

Colors (needle bars) can be selected up to 99 times in any desired sequence. | |||

*''' | *'''Threas Tension Releasing Device (Patented)''' | ||

During sewing. Tension is automatically released an all unused threads. | |||

*''' | *'''Independent Take-up Lever Drive System''' | ||

The take-up lever only for the needle bar being used, operates while the other levers are at rest: this prevents the threasd from being entangled. | |||

This system also allows the threads to run smoothy for constant ATH trimming. | |||

*'''Both Binary and Ternary Tape formalts can be used''' | |||

*'''Speed Change''' | |||

Speeds can be automatically changed between High and Low ranges by tape code data: key operations also allow you to adjust the speeds as required. | |||

* | *'''Desing Coordinate''' | ||

A desing can be mirrored both horizontally and vertivally and also rotated in 90-degree increments: 8-diferrent positions can be createcd | |||

*'''Memory System''' | |||

Up to 99 desings can be memorized in this system with the remaining capacity displayed in the stitches. (A standard 128.000- stitch memory card is included.) | |||

*'''Automatic Repeat''' | |||

A desing can be repeatedly stitche-d up to 9 times during memory operation. | |||

*'''Frame back function''' | |||

When a design is damaged by thread Breakage, the frame can be stitched back for repairs up to 500 stitches during memory and tape operation. Also, as soon as the single-head operation to restitch the damaged part is completed, the other heads resart sewing. | |||

'''''The | *'''Frame Forward''' | ||

The frame can be stepped forward without stitching up to the end of the design. | |||

*'''Scaling Up/Down Function''' | |||

A design can be scaled up or down in 1-% increments from 50% up to 200%. | |||

* ''' | *'''Return Origin''' | ||

Simple key operations return the frame to the design starting point. | |||

*'''Offset Function''' | |||

In addition to the design starting point, a secondary starting point can be set for automatic operation: this function facilitates frame changing, thread trimming, etc. | |||

*''' | *'''Display Function''' | ||

Various messages are digitally displayed: R.P.M., available memory, and stitch count, stop factors emergency stop codes, etc. | |||

*''' | *'''Automatic Thread Trimming Device (ATH)''' | ||

This device has the function of trimming both upper and under threads automatically at the same time by pre-punched tape code when embroidery is completed, color change is performed, or stitching is jumped from one design to another. | |||

Latest revision as of 21:11, 24 May 2016

{{#invoke:Infobox|infobox}}

The Tajima TMEF were flat machines besides a few exception models.

TMEF came in several different models such as the TMEF-HCG, TMEF-S, etc.

TMEF machines are bridge type embroidery machines.

TMEF Series & TMEF H

Tajima also made a TMEF-HC version of the TMEF which was a large sewing area bridge version of the HC model (which is typically Arm style)

TAJIMA is the technological leader in the embroidery industry.

| Model | Heads | Needles | EMB Space / Head | Max SPM | Pwr Cons. | Years | Color |

|---|---|---|---|---|---|---|---|

| TMEF-HC606 (G1) | 6 | 6 | emb Space | SPM | POWEW | 1990-1992 | Green |

| TMEF-HC612 (G1) | 12 | 6 | emb Space | SPM | POWEW | 1990-1992 | Green |

| TMEF-HC904 (G1) | 4 | 9 | emb Space | SPM | POWEW | 1990-1992 | Green |

| TMEF-HC906 (G1) | 6 | 9 | emb Space | SPM | POWEW | 1990-1992 | Green |

| TMEF-HC912 (G1) | 12 | 9 | emb Space | SPM | POWEW | 1990-1992 | Green |

| TMEF-HC906 (G2) | 6 | 9 | emb Space | SPM | POWEW | 1993-1994 | Green |

| TMEF-HC912 (G2) | 12 | 9 | emb Space | SPM | POWEW | 1993-1994 | Green |

FEACTURES & FUNCTIONS

- ACCURATE FRAME DRIVE & POWERFUL MAIN-SHAFT DRIVE MOTOR.

A special stepping motor featuring almost permanent life and extremely high accuracy is used for assuring stable frame driving.

- SPEED CHANGE

Simple knoh control or (push a numeral key) of infinitely variable speed (within range), and two speeds controlled by tape data (computer) to reduce thread breakage.

- FRAME BACK

If embroidery is damaged because of a thread break or bobbin runout, the frame can be moved backward to the starting point (500 stitches) if operating from tape. Once restarted the machine sews independently on heads where damage occurred before automatically restarting all heads.

- FRAME FORWARD

Frame can be manually stepped forward without stitching

- LON G LASTING STORAGE OF TAPE DATA

If the machine is stopped in the middle of a design and left idle for a long time, the tape data remains stored in memory or (buffer). When restarted the machine will begin to sew at the exact spot where it was stopped

- DESIGN COODINATE CHANGE SYSTEM

16 [8] symmetrical desing positions are possible in 45 degree [90 degree] increments at the push of a button.

- PATENTED AUTOMATIC NEEDLE BAR SELECTOR (FOR EASY NEEDLE/ COLOR SEQUENCING)

Needle bars can be selected for any color change sequence. Color change is possible up ti 99 times.

- JUMP STITCH DEVICE

- AUTOMATIC REPEAT

Embroidery of a design having the same color pattern can be automatically repeated up to 81 [9] times when operating from memory. [ 9 times when operating from tape]

TMEF

With the addition of the TMEF-S series (streamlined with useful functions for easier operation) the TMEF series is now complete. It is the top model series in the embroidery industry today.

The 900 series is the world’s first is the world’s first and only 9 needle machine.

The 300 series (3-needle), 400 series (4-needle), and the 600 series (6-needle) are available in many configurations with 6 to 24 heads and from standard to large embroidery design fields.

Brochure

The following information has been taken from a Tajima TMEF Brochure:

THE TMEF SERIES IS THE INDUSTR’S ANSWER TO THE EVER-CHANGING REQUIEREMENTS IN THE WORLD OF FASHION.

SETTING CAPACITY

- Sealing (up/down)1%-100%(original size)-100%

- Stitch density of the satin and/or the fill stitch (increase/decrease)-90% - 0%(original size)-100%

- Stitch length of the fill and/or the running stitch (increase/decrease)-90% - 0% (original size) -100%

- Enlarge or reduce your design and let TSP change the stitch density automatically.

- Rotate your design to any angle.

- A design can be mirrored by centering on Y axis.

- TSP TAJIMA STITCH PROCESSOR (Option)

- TRUE SCALING (UP AND DOWN) OF DESIGN TAPES WITH TAJIMA’S REVOLUTIONARY TSP WITH AUTOMATIC STITCH DENSITY COMPENSATION…AND MORE!!

TMEF-H

Brochure

The following information has been taken from a Tajima TMEF Brochure:

The Creative approach to faschion

With a small twist, an interesting desing or a delicious fragrance, an ordinary, everyday scene stars to look different. It´s the same way with the art of looking good. Toss out conventional ideas and jump into somethimg new. We at tajima want to help strengthen the bonds between the clothes and the wearer and help you create more exciting fashions.

That special touch of beauty:

The pursuit of beauty is eternal Everyone Has some special quality, and some take the adventurous path in highlighting it. Today, attention is focusing on embroidery, which adds beauty and imagination to clothing and accessories. We at Tajima want to help you achieve those moments of creativity and realize them senstively, vividly, and any way you desire.

The Tajima TMEF-H machine dimension information

| Models | Heads | Head Interval | Emb. Space (D x W mm) | All-head Border/Continuous Design (D x W mm) | Table size (L x W mm) |

|---|---|---|---|---|---|

| TMEF-H608-908 | 8 | 400 | 450 x 400 | 450 x 3,200 | 1,340 x 4,220 |

| TMEF-H610-910 | 10 | 325 | 450 x 325 | 450 x3,250 | 1,340 x 4,195 |

| THEF-H610-910 | 10 | 400 | 450 x 400 | 450 x 4,000 | 1,340 x 5,020 |

| THEF-H612-912 | 12 | 275 | 450 x 275(550) | 450 x 3,300 | 1,340 x 4,470 |

| THEF-H612-912 | 12 | 345 | 450 x 345 | 450 x 4,140 | 1,340 x 5,110 |

| THEF-H615-915 | 15 | 275 | 450 x 275 | 450 x 4,125 | 1,340 x 5,020 |

| TMEF-H616 | 16 | 240 | 450 x 240 (480) | 450 x 3,840 | 1,340 x 4,960 |

| TMEF-H618 | 18 | 230 | 450 x 230 | 450 x 4,140 | 1,340 x 5,010 |

| TMEF-H620 | 20 | 200 | 450 x 200(400) | 450 x 4,000 | 1,340 x 5,020 |

TMEF H Table specifications

| Standard equipment | 8-channel tape reader |

|---|---|

| Options | Additional IC multiplex Memory (256,000 stitches max)Under threas control, Boring device, Reader/Handler, Stitch processor, Floppy disck drive , Power condenser etc |

| Stitch length | Ternary scale :0,1 --12,1mm, Binary scale : 0,1 --12,7mm |

| Speed | Speed |

| Motor | Speed variable motor x 1. Stepping motor x 2 |

| Electricity | 3-phase 220V/380V. 50Hz/60Hz Single-phase 200V,220V,230V,240V. 50Hz/60Hz |

| Electric consumption | 1,0Kw ( 3 phase 200V) |

Main Feactures and Functions for the H-series

- Accurate Frame Drive

For stable frame driving,special stepping (pulse) motors are used. These motors feature an almost permanent life and pin-point accuracy.

- Automatic Needle Bar Selector (Pantented)

Colors (needle bars) can be selected up to 99 times in any desired sequence.

- Threas Tension Releasing Device (Patented)

During sewing. Tension is automatically released an all unused threads.

- Independent Take-up Lever Drive System

The take-up lever only for the needle bar being used, operates while the other levers are at rest: this prevents the threasd from being entangled. This system also allows the threads to run smoothy for constant ATH trimming.

- Both Binary and Ternary Tape formalts can be used

- Speed Change

Speeds can be automatically changed between High and Low ranges by tape code data: key operations also allow you to adjust the speeds as required.

- Desing Coordinate

A desing can be mirrored both horizontally and vertivally and also rotated in 90-degree increments: 8-diferrent positions can be createcd

- Memory System

Up to 99 desings can be memorized in this system with the remaining capacity displayed in the stitches. (A standard 128.000- stitch memory card is included.)

- Automatic Repeat

A desing can be repeatedly stitche-d up to 9 times during memory operation.

- Frame back function

When a design is damaged by thread Breakage, the frame can be stitched back for repairs up to 500 stitches during memory and tape operation. Also, as soon as the single-head operation to restitch the damaged part is completed, the other heads resart sewing.

- Frame Forward

The frame can be stepped forward without stitching up to the end of the design.

- Scaling Up/Down Function

A design can be scaled up or down in 1-% increments from 50% up to 200%.

- Return Origin

Simple key operations return the frame to the design starting point.

- Offset Function

In addition to the design starting point, a secondary starting point can be set for automatic operation: this function facilitates frame changing, thread trimming, etc.

- Display Function

Various messages are digitally displayed: R.P.M., available memory, and stitch count, stop factors emergency stop codes, etc.

- Automatic Thread Trimming Device (ATH)

This device has the function of trimming both upper and under threads automatically at the same time by pre-punched tape code when embroidery is completed, color change is performed, or stitching is jumped from one design to another.