Floppy disk drive

Most embroidery machines were built with a floppy disk drive as the method to input designs even as late as the mid 2000s. These drives used a floppy disk, or diskette, as their disk storage medium. The floppy disk is composed of a disk of a thin magnetic storage medium sealed in a rectangular plastic carrier lined with fabric that removes dust particles. They are read and written by the floppy disk drive (FDD).

By 2010, computer motherboards were rarely manufactured with floppy drive support; 3 1⁄2 " floppies could be used as an external USB drive, but 5 1⁄4 ", 8 ", and non-standard drives could only be handled by old equipment.

Floppy disk drives are still around, especially with legacy industrial equipment such as embroidery machines, CNC machines, musical equipment, laser cutters and other specialty machines.

Floppy Disk Upgrade

Because of the limitations of mechanical floppy disk drive technology, legacy industrial equipment that is still in operation today often uses a FloppyToUSB upgrade device in which the floppy disk drive is replaced with a floppy disk drive emulator and a USB flash drive. This enables aging equipment to take advantage of superior solid state drive technology which has no moving mechanical components, in addition to other benefits (see floppy disk weaknesses below).

Floppy Disk Weaknesses

The owner manual for the Tajima Neo II built in 2002 and which came with a floppy disk drive states:

• Do not put the floppy disk near magnets or a TV set. • Do not expose the floppy disk to excessive heat, humidity, or direct sunlight. • Do not place objects on the floppy disk. • Do not stack floppy disks to store. • Floppy disks do not last eternally. Data must be copied to backup floppy disks for storage. • Do not use damaged or deformed floppy disk, otherwise the floppy disk drive could be damaged. • Clean the floppy disk drive once a month using a cleaning disk. If the head is foul, trouble to reading/writing data could occur. • If a floppy disk is inserted impetuously, pressing the eject button may fail to eject the floppy disk. This could cause the floppy disk to be damaged and, in addition, the floppy disk drive could be damaged.

3.5-inch floppy disk - "Microfloppy"

In the early 1980s, a number of manufacturers introduced smaller floppy drives and media in various formats. A consortium of 21 companies eventually settled on a 3.5-inch floppy disk (actually 90 mm wide), similar to a Sony design, but improved to support both single-sided and double-sided media, with formatted capacities of 360 KB and 720 KB respectively.

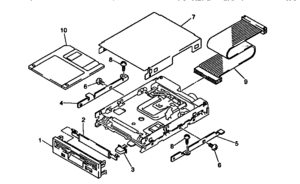

Disk drive bay form factor

3.5″ Standard Floppy Disk Drive. 3.5″ bays, like their larger counterparts, are named after diskette dimensions not actual size; their actual dimensions are 4″ wide by 1″ high (102 mm × 25 mm). The dimensions of a 3.5″ drive are specified in the SFF standard specifications SFF-8300 and SFF-8301 which were incorporated into the EIA-740 specification by the Electronic Industries Association (EIA).

3.5-inch Slim Floppy Disk Drive. The "slim" floppy disk drive, also often referred to as a "half-height" drive, is the same length and width (approximately as there are small variations) as the standard floppy disk drive. The slim drive designation refers to the height; it is .5-inch tall (versus the 1-inch tall standard floppy disk drive).