Difference between revisions of "Oiling the Butterfly embroidery machine"

| (49 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

This article '''Oiling the Butterfly Embroidery Machine''' can generally be used on most all newer single head [[Embroidery Machines]] | |||

{{for|the Butterfly Embroidery Machine Portal|Portal:Butterfly}} | |||

==Oiling the Butterfly Embroidery Machine== | |||

To ensure your Butterfly embroidery machine enjoys a long and healthy life, it is important to oil the machine at the required intervals. However, please take care not to over-oil the machine as oil can accumulate and potentially get into the electronics, onto garments and/or other parts of the machine that were not designed to be oiled. | To ensure your Butterfly embroidery machine enjoys a long and healthy life, it is important to oil the machine at the required intervals. However, please take care not to over-oil the machine as oil can accumulate and potentially get into the electronics, onto garments and/or other parts of the machine that were not designed to be oiled. | ||

When oiling the Butterfly machine, standard sewing or embroidery machine oil should be used. It is recommended to oil the machine '''''after''''' each shift to give the oil time to settle. When starting the machine at the next shift for the first time, it is recommended to sew a sample run and to sew each run using | When oiling the Butterfly machine, standard sewing or embroidery machine oil should be used. It is recommended to oil the machine '''''after''''' each shift to give the oil time to settle. When starting the machine at the next shift for the first time, it is recommended to sew a sample run and to sew each run using [[Solvy]]. Solvy helps to catch any excess oil from dripping on and staining garments. | ||

It is also not recommended to oil parts of the machine that are not specified in this guide. | It is also not recommended to oil parts of the machine that are not specified in this guide. | ||

==Front needle springs== | |||

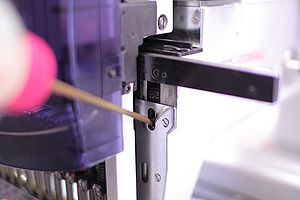

Oil the front needle springs once every twenty (20) hours of embroidery machine operation. Oil each bar through the slotted opening. Do not place more than one drop per bar per eight hour shift. There is a piece of felt material inside the head that absorbs the oil and lubricates the shaft. | |||

[[File: Front needle bars oil.jpg|left|thumb|alt=oil front needle springs|Oil the front needle springs through the opening]] | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

==Main shaft bearings== | |||

There are two stickers on either side of the main shaft along with an opening to easily add oil. Oil as indicated on the sticker. | |||

[[File: Head oil.jpg|left|thumb|alt=Oil the main shaft bearings at the two locations indicated on the machine|Oil the main shaft bearings at the two locations indicated on the machine]] [[File: Main shaft oil.jpg|center|thumb|alt=Oil the main shaft bearings at the two locations indicated on the machine|Oil the main shaft bearings at the two locations indicated on the machine]] | |||

<br /> | |||

<br /> | |||

==Hook shaft bearings== | |||

Oil the hook shaft bearings (two locations). | |||

[[File: Hook shaft front.jpg|left|thumb|alt=Oil the hook bearings on the machine|Oil the hook bearings on the machine]] [[File: Hook shaft back.jpg|center|thumb|alt=Oil the main hook bearings on the machine|Oil the hook bearings on the machine]] | |||

==Reciprocator shaft== | |||

Also be sure to oil the reciprocator shaft every 16-32 hours of operation. There is a channel inside for the oil to travel to the middle of the head to reach the shaft. | |||

[[File: Reciprocator shaft oil.jpg|left|thumb|alt=Oil the reciprocator shaft|Oil the reciprocator shaft]] | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

==Pressure foot shaft and linkages== | |||

Oil the pressure foot shaft and linkages. Oil into the center of the linkage screws (two screws). Move the head to needle one (1) to expose the ports. | |||

[[File: Pressure foot links1.jpg|left|thumb|alt=Oil the hook bearings on the machine|Oil the hook bearings on the machine]] [[File: Pressure foot links2.jpg|center|thumb|alt=Oil the main hook bearings on the machine|Oil the hook bearings on the machine]] | |||

[[File: Pressure foot links3.jpg|left|thumb|alt=Oil the hook bearings on the machine|Oil the hook bearings on the machine]] | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

<br /> | |||

==Hook guide rail== | |||

Oil the hook guide rail often. | |||

[[File: Hook guide rail oil.jpg|left|thumb|alt=Oil the hook guide rail often|Oil the hook guide rail often]] | |||

Latest revision as of 20:09, 9 November 2013

This article Oiling the Butterfly Embroidery Machine can generally be used on most all newer single head Embroidery Machines

Oiling the Butterfly Embroidery Machine

To ensure your Butterfly embroidery machine enjoys a long and healthy life, it is important to oil the machine at the required intervals. However, please take care not to over-oil the machine as oil can accumulate and potentially get into the electronics, onto garments and/or other parts of the machine that were not designed to be oiled.

When oiling the Butterfly machine, standard sewing or embroidery machine oil should be used. It is recommended to oil the machine after each shift to give the oil time to settle. When starting the machine at the next shift for the first time, it is recommended to sew a sample run and to sew each run using Solvy. Solvy helps to catch any excess oil from dripping on and staining garments.

It is also not recommended to oil parts of the machine that are not specified in this guide.

Front needle springs

Oil the front needle springs once every twenty (20) hours of embroidery machine operation. Oil each bar through the slotted opening. Do not place more than one drop per bar per eight hour shift. There is a piece of felt material inside the head that absorbs the oil and lubricates the shaft.

Main shaft bearings

There are two stickers on either side of the main shaft along with an opening to easily add oil. Oil as indicated on the sticker.

Hook shaft bearings

Oil the hook shaft bearings (two locations).

Reciprocator shaft

Also be sure to oil the reciprocator shaft every 16-32 hours of operation. There is a channel inside for the oil to travel to the middle of the head to reach the shaft.

Pressure foot shaft and linkages

Oil the pressure foot shaft and linkages. Oil into the center of the linkage screws (two screws). Move the head to needle one (1) to expose the ports.

Hook guide rail

Oil the hook guide rail often.