Tajima TME-DC

{{#invoke:Infobox|infobox}}

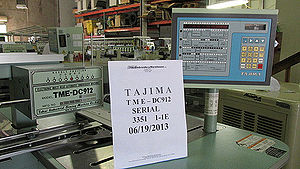

The Tajima TME-DC was the next model up from the TME-HC model produced the previous years before.

Unlike the Tajima TME-HC machine, the Tajima TME-DC models came standard with a Floppy Disk Drive. The Tajima DC series also came with upgraded control panel, motors, and motor controllers.

TME-DC Series

For the Tajima TME-DC user manual see Tajima TME-DC User Manual

Many models of the Tajima DC also came with Hydraulic Tables but, standard removable table tops were still available on some for a lesser price. The Tajima TME-DC models were available in 6, 12, 15 and 20 heads.

The early machines built in the early and mid 1990s were mostly 9 needles. Around year 2000 most all models were standard 12 needles.

The Tajima TME-DC series is an Arm Type (not Bridge Type) embroidery machine.

The Bridge Type equivalent is the Tajima TMFD machine

In 1994 Tajima released the TME-DC series embroidery machine.

The TME-DC machine was the first Tajima multihead machine with a floppy drive. The machine can also be upgraded to FloppyToUSB

1994-1996

The first models of the Tajima TME-DC series were green machines. The only green machines were produced 1994 - 1996. Some of the 1996 models might be white color. The machine either had removable tables or hydraulic tables.

The machine was very similar to the earlier TME-HC model but, had upgraded electronics including the control panel, IMM, IDM, motor, motor controller, etc. The machine also had a floppy drive which can be upgraded to Floppy To USB

1997-1999

The TME-DC machine changed color scheme and logos around 1996. The 1997 models of the TME-DC series were white but were otherwise very similar to the previous TME-DC machines. The white version was available later in 12 needles.

TME-DC Specifications

| Model | Heads | Needles | EMB Space / Head | Max SPM | Pwr Cons. | Years | Color |

|---|---|---|---|---|---|---|---|

| TME-DC906 (G1) | 6 | 9 | 300mm x 360mm | 800 | POWEW | 1994-1996 | Green |

| TME-DC912 (G1) | 12 | 9 | 300mm x 360mm | 800 | POWEW | 1994-1996 | Green |

| TME-DC606 (G1) | 6 | 6 | 300mm x 360mm | 800 | POWEW | 1994-1996 | Green |

| TME-DC918 (G1) | 18 | 9 | 300mm x 360mm | 800 | POWEW | 1994-1996 | Green |

| TME-DC906 (G2) | 6 | 9 | 300mm x 360mm | 800 | POWEW | 1997-1998 | White |

| TME-DC912 (G2) | 12 | 9 | 300mm x 360mm | 800 | POWEW | 1997-1998 | White |

| TME-DC906 (G2) | 6 | 9 | 300mm x 360mm | 800 | POWEW | 1997-1998 | White |

| TME-DC918 (G2) | 18 | 9 | 300mm x 360mm | 800 | POWEW | 1997-1998 | White |

| TME-DC1206 (G2) | 6 | 12 | 300mm x 360mm | 800 | POWEW | 1998-2002 | White |

| TME-DC1212 (G2) | 12 | 12 | 300mm x 360mm | 800 | POWEW | 1998-2002 | White |

| TME-DC1218 (G2) | 18 | 12 | 300mm x 360mm | 800 | POWEW | 1998-2002 | White |

TME-DC Features

The following features list has been provided by Tajima technical details list

- Accurate Frame Drive: Special stepping (pulse) motors, featuring an almost permanent life and pinpoint accuracy. Also assures stable and quiet frame driving.

- Automatic Needle Bar Selector (Patented): Colors (needle bars) can be selected up to 99 times in any desired sequence.

- Independent Take-Up Lever Drive System: Only the specific take-up lever being used operates, while the others remain at rest, preventing thread tangling and assuring smooth thread running for constant ATH trimming.

- Individual Tension Base: The individual thread tension base moves together with the needle bar case at color changes, maintaining stable thread tension during embroidery.

- Uses Both Binary and Ternary Tape Formats

- Built-In Floppy Disk Drive: Drive can read and write designs in Tajima format as well as other manufacturer's formats

- Speed Change: Speeds can be changed automatically between high and low ranges by design data, as well as through key operations.

- Scale Up/Down, Rotate: Designs can be scaled down to 50% or up to 200% in increments of 1%. In addition, designs can be rotated in 1° increments.

- Memory: Standard memory is 304,000 stitches accommodating up to 99 designs.

- Repeat: Designs can be repeatedly stitched up to 99 times in either the X-axis or Y axis.

- Frame Back: The frame can be backed up in 1-stitch, 3-stitch units and by color change units to facilitate production after a thread break or bobbin run out. In addition, single-head operation to restitch damaged portions of the design can be performed.

- Frame Forward: The frame can be stepped forward without stitching.

- Origin Return: The frame can be returned to the design starting point while the machine is stopped, either manually or automatically, even if the end point is different from the starting point.

- Automatic Offset/Manual Offset: To facilitate appliqué work and frame changing, the frame can be automatically moved to the preset offset point. After tasks are completed, the frame can be returned to the point at which the offset movement began. In addition, if the frame has been moved using the Manual Frame Travel keys while the machine is stopped, simple key operations enable the frame to return to the previous stitch point.

- Automatic Thread Trimming and Holding Device (ATH): the ATH device can be automatically operated by the design data, improving the quality of finished goods, as well as increasing productivity. Manual ATH operations are also possible at any point during the embroidery of the design.

- Power Failure Control Measures: Operation of the machine can continue after power failure, continuing the design and eliminating displacement.

- FM and DG Connections: Machines can be connected to the FM/DG/ML systems to make embroidery directly and speed up sample production.

- Network System NW-II and Monogramming: The machine can be used as an instant monogramming system, and operations of other machines can be controlled through a communications network.

- AC Servo Motors: The use of servo motors in the main shaft provides more powerful and stable embroidery, even with large multihead machines.

- Auto Sub-Table: Table can be raised or lowered using the operation panel for easy switching between standard embroidery and embroidery on finished goods.

- Wide Cap Frame: Allows for embroidery of up to 270° on finished caps.

- Control Panel: Easy-to-operate, yet sophisticated control panel with both LED and LCD displays

TME-DC Options

The following options list has been provided by Tajima technical details list

- Cording Device

- Jumbo Rotary Hook

- Boring Device

- Noise Reduction

- FM Note

- NWII

Tajima Legend

Tajima used several codes in their models that described basic features of the machines. The letters in the model number usually

- TME

- Machines with TME in their model without any other letters (numbers only) is a very late 1970s - 1990 flat only machine.

- TME-C

- Predecessor to the TME, a Tajima machine with a C in it represents Cylinder (tubular) embroidery. Therefore machines with the letter C in their model, have removable tables.

- TME-HC, TMEF-H, H

- Models with H in their model have the H model control panels. A TME-HC is an Arm Type machine with removable tables and the H model control panel. A TMEF-H machine is a flat machine with the H model control panel.

- TMEF

- Machines with the F code are Bridge Machine (not arm type). If there are not more letter codes then this machine is a flat only machine (does not to tubular or caps).

- TMM

- TMM machines were collaboration Melco and Tajima machines. These machines have a Melco control panel/keyboard.

Tajima Years, Date or Age

The year of the Tajima machine can usually be found on a sticker behind the machines control panel or power boxes. These years are usually the year that the machines electronics were Quality Control checked at the Japan factory. The months listed on these stickers will probably be different. It usually took about 3 months from production to delivery to the original customers location. Later models had the production year stamped on the data plate.

If the machine is old and does not have a sticker, then the machine is probably older than 1990.

Buying

Tajima embroidery machines are probably one of the best machines on the market. They are more expensive that most all competing models but, they are very solidly built and have a good resell market. There are a lot of embroidery machine technicians available world wide and parts are pretty easy to find even for older models.

Selling

TheEmbroideryWarehouse buys and sells most every make and model of Tajima embroidery machines located within the continental USA. They also purchase parts, parts machines, salvage machines and most everything else related to embroidery equipment.